One-Stop Watch Solution

Service

One-Stop

Watch Solution

Watch Solution

CONSULTATION

We are specialized in ODM and OEM of both quartz and mechanical watches. We fully capture COGS target, product inspiration, value proposition and strategy from customers. Comprehensive quote is also provided with achievable timeline to realize product launch plan.

DESIGN & DEVELOPMENT

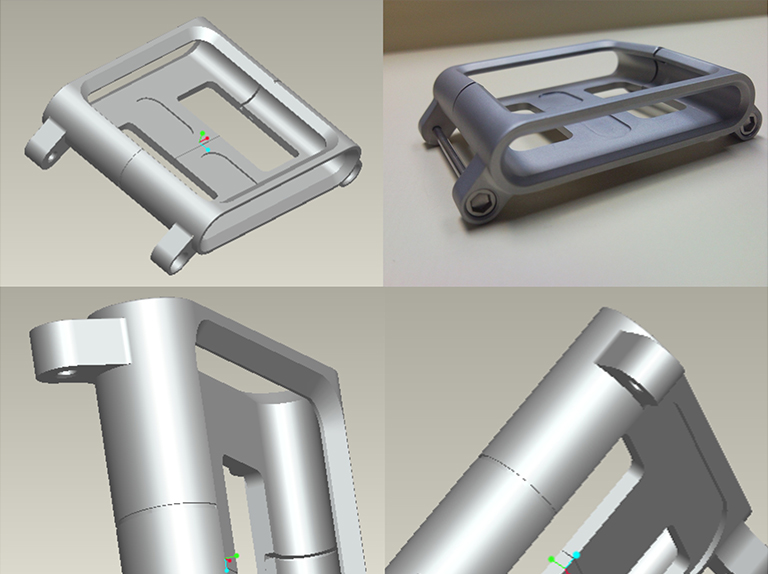

Industrial Watch Design. Our experienced design engineering team is sensitive with current market trends to realize product at its excellence. 2D/3D design rendering are provided to interact initial concept to finalization.

Detailed Engineering Watch Design. Technical details are considered thoroughly to meet design requirement at its best optimization on production & cost efficiency. To provide the best competitive edge in terms of cost, quality and delivery.

Detailed Engineering Watch Design. Technical details are considered thoroughly to meet design requirement at its best optimization on production & cost efficiency. To provide the best competitive edge in terms of cost, quality and delivery.

PROTOTYPING

Rapid CNC Sampling. In-house HK workshop strengthens our rapid sampling capability and IP protection during development stage. We aim at swift moving momentum to meet current fast changing product life cycle.

Design Validation. Going through validation during sampling stage, to ensure product quality and reliability. And construct preliminary quality control standards.

Design Validation. Going through validation during sampling stage, to ensure product quality and reliability. And construct preliminary quality control standards.

PRODUCTION

Real-time Tracking. Our MRP system enable complete supply chain visibility, allowing real-time tracking of purchasing order. Customer can trace order status in very short period of time.

Assembly Services. Watch assembly then takes place in our factory in Dongguan, China, through highly-trained staff.

Assembly Services. Watch assembly then takes place in our factory in Dongguan, China, through highly-trained staff.

QUALITY & TESTING

Quality Control. We have an extensive range of machineries for intensive quality control on all incoming watch components. FMEA tool is widely adopted to find out critical quality control points for complete product.

Watch assembly and final quality control processes take place in our Dongguan factory to ensure reliability. All watches are executed with quality test of Burn-in, accuracy, movement function, hands alignment and water resistance.

Watch assembly and final quality control processes take place in our Dongguan factory to ensure reliability. All watches are executed with quality test of Burn-in, accuracy, movement function, hands alignment and water resistance.

PROJECT TIMELINE

Quotation

0.5 - 1 week

- Product Specification Captured

- Tooling & Setup

- Costing & Quotation

Project Start

0.5 week

- Detail Requirement Captured

- Professional Advices

- Scheduling

Development

4 - 6 weeks

- Industrial and Engineering Design Exchange

- 3D Rendering Virtual Visualization

- Sampling

- Testing & Validation

Approval

0.5 week

- Sample Delivered & Approval

- Revision/ Final specification confirmation

Manufacturing

11 - 13 weeks

- Components Ordering

- Design for Manufacturing

- Testing Design

- Manufacturing

- Packaging

Quotation

0.5 - 1 week

- Product Specification Captured

- Tooling & Setup

- Costing & Quotation

Project Start

0.5 week

- Detail Requirement Captured

- Professional Advices

- Scheduling

Development

4 - 6 weeks

- Industrial and Engineering Design Exchange

- 3D Rendering Virtual Visualization

- Sampling

- Testing & Validation

Approval

0.5 week

- Sample Delivered & Approval

- Revision/ Final specification confirmation

Manufacturing

11 - 13 weeks

- Components Ordering

- Design for Manufacturing

- Testing Design

- Manufacturing

- Packaging

Jewelry and

Accessory Service

Accessory Service

We also provide professional stainless steel jewelry and accessory OEM & ODM services for many renowned brands, from the design concepts to the finished products. Product range covers pendant, bangle, rings, pen, carabiner, car components, and apple store’s accessory; and anything you can imagine, our experienced design engineering team can meet your design requirement at its best optimization in term of production smoothness and cost efficiency.

Our Process & Timeline

Quotation

1 - 2 weeks

- Evaluate Product design

- Product specification and Requirement

- Costing for tooling, setup & production

- Quotation

Project Start

1 week

- Project scheduling

- Professional Advices

- Project confirmation

Development

2 - 4 weeks

- Industrial and Engineering

Design exchange - Technical drawing

- 3D visualization & rendering

- Product Design confirmation

Prototype

4 - 6 weeks

- Engineering Prototype

- Testing & Validation

Approval

1 week

- Sample delivered & approval

- Sample review

- Revision / final specification

confirmation

Manufacturing

8 - 10 weeks

- Components Ordering

- Manufacturing

- Production Validation

- Production sample testing & validation

- Quality Control

- Packaging & Shipment

Quotation

2 - 4 weeks

- Evaluate Product design

- Product specification and Requirement

- Costing for tooling, setup & production

- Quotation

Project Start

1 week

- Project scheduling

- Professional Advices

- Project confirmation

Development

2 - 4 weeks

- Industrial and Engineering

Design exchange - Technical drawing

- 3D visualization & rendering

- Product Design confirmation

Prototype

4 - 6 weeks

- Engineering Prototype

- Testing & Validation

Approval

1 week

- Sample delivered & approval

- Sample review

- Revision / final specification

confirmation

Manufacturing

8 - 10 weeks

- Components Ordering

- Manufacturing

- Production Validation

- Production sample testing & validation

- Quality Control

- Packaging & Shipment

Our Materials

Stainless Steel

The two most widely used austenitic stainless steel are 304L and 316L within our industry. 316 stainless steel contains molybdenum which drastically enhances corrosion resistance and stabilizes nickel release; while 304 is less corrosive resistant than 316L but it is an economical and practical choice for most environment because of its hardness for durability.

Brass

Brass is an alloy made primarily of copper and zinc. Its bright gold appearance can range in color from red to yellow depending on the amount of zinc added to the alloy. The soft property offers the common uses to some bendable, adjustable and low friction requirement jewelries, like bangle, ring and choker.

Aluminum

Aluminum is one of the lightest metals in the world, with durable and ductile properties. And its surface covered an oxide film layer offers protection from corrosion. It is prefect for the structural accessories, like door hinge, door handle, mobile phone case & accessories and car components. Wide range of colors can be applied on surface through anodizing process.

Titanium

Titanium is a high strength, lightweight and exceptional corrosion resistance refractory metal. It is 40% lighter in weight than steel which is commonly used for high-end product. Titanium jewelry is rising popularity with men in particular. Many men find that titanium looks more masculine because of its sleek and space-age color.

Plastic

Right plastic selection is the key to achieving best product performance. We align experience molder to choose best material at its best optimization on hardness, flexibility, weight and cost.

Logistic

Service

Service

Under demand of global business environment, Wincy equips strong network of reliable and validated forwarders that we have long-term relationships, to uphold our service standard to deliver different countries world-wide on time.

We treat your shipment like ours in getting your product from our doorstep to yours.

We treat your shipment like ours in getting your product from our doorstep to yours.

Crowdfunding

Successful Case

Successful Case

Welcome, Creators !! We have been supporting Crowdfunders since 2010. Our all in one solution helps you navigate product development and mass manufacturing in Hong Kong and China. Let’s bring your product to life with us.

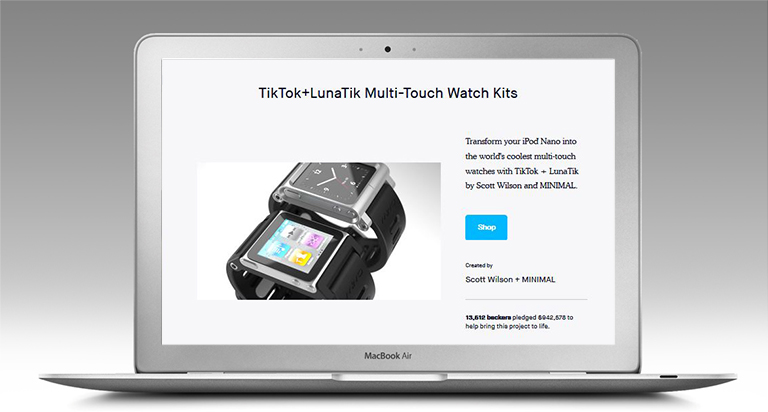

Tiktok + LunaTik

By Scott Willison (2012 National Design Award Winner)

A simple transformation of the Ipod Nano into a wearable item Crowdfunding

Crowdfunding Highlight

It is the 1 st project closed to US$1 Million in 30 days, which has been credited with “kickstarting” kickstarter.

Our Involvement and Challenge

We well defined product and process engineering requirements, and fit with manufacturing resources and skills. We dug deep into production control to overcome uneven shrinkage at Tikok and thin wall machining at Lunatik. Combine tolerance consideration is also one of most critical to achieve project success.

Dango Modular Watches

By Charlie Carroll

An innovative interchangeable lugs watch.

Crowdfunding Highlight

Hit the crowdfunding goal in less than 3 hours, and finally reached over 500% of goal.

Our Involvement and Challenge

Working with Dango was an exciting challenge as they brought out many innovative ideas that never seen before. Wincy therefore supports two design patent applications to realize the project, interchangeable lugs and flex buckle. In the production aspect, tolerance control is critically important among all areas especially interchangeable function. A breakthrough top loaded turning bezel structure is adopted to maximizing the dial opening of the Dive watch, to unify origin design atmosphere among whole collection.

Site Map

About Us

Our Customers

Services

Catalog

Manufacturing

Contact Us